The European Biomass Association (AEBIOM) is the common voice of the bioenergy sector with the aim to develop a sustainable bio energy market based on fair business conditions. The European Pellet Council (EPC) is an umbrella organization representing the interests of the European wood pellet sector. There are three major works as below: First, Responsible for quality, safety, education and related information. Second is promotes using capacity in Europe. Third is coordinates ENPLUS.

Why do wood pellets need a new certificate?

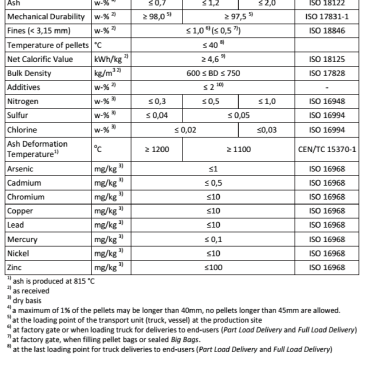

New European standards for solid biomass fuels have been introduced in 2011. They include a standard for wood pellets (EN 14961-2) which ENplus helps to implement all over Europe. The individual national standards are no longer valid. EN 14961-2 was superseded by ISO 17225-2 standard in 2014. With the handbook 3.0 ENplus changes to follow the ISO standard.

Which quality classes exist in ENplus?

The standard includes quality classes A1 and A2 that are also implemented via ENplus. Class A1 is the premium quality used in private household boilers or stoves. A1 pellets produce the least amount of ash and fulfill the highest requirements. Class A2 is used in larger installations and produces more ash.

What is new in ENplus?

Until now quality labels only focused on the production. ENplus goes one step further and includes in addition to the strict production criteria also the trade afterwards. Every (intermediary) trader until the final delivery to the consumer is controlled, thus ensuring adequate transport and storage along the chain.

How does ENplus ensure the right quality?

ENplus is a very transparent system. Identification numbers for both producers and traders secure an extensive traceability of the product. ENplus is the new benchmark for the consumers and the operation of their boilers and stoves.

How is the conformity to ENplus regulations checked?

Pellet plants get audited once a year to inspect the production process and the quality management. Pellet samples are taken and analyzed in specialized labs. Traders are checked as well and agree to follow strict rules. Producers and traders are free to choose any accredited company listed on the ENplus website for the audits and tests. Training courses for new auditors are organized to ensure the same quality of audits all over Europe.

How is the market uptake of ENplus in Europe?

ENplus is spreading quickly since its first introduction in Germany in 2010. By 2015 there are ENplus certified pellet producers in 34 countries (Austria, Bosnia & Herzegovina, Belgium, Bulgaria, Brazil, Belarus, Canada, Croatia, Czech Republic, Denmark, Estonia, France, Germany, Greece, Hungary, Ireland, Italy, Latvia, Lithuania, Montenegro, Malaysia, Netherlands, Poland, Portugal, Romania, Russia, Serbia, Switzerland, Spain, Sweden, Slovenia, Slovakia, Ukraine, United Kingdom and USA). The total production of ENplus pellets is around 6 million tons per year.

Contact Us Now !

Fill in Request

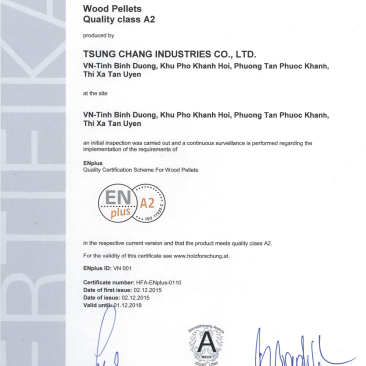

Through Tsung Chang Industries unique technique, our factory in Vietnam is the first manufacturer pass ENPLUS A2. The identification number is VN001. If you need to more further information and cooperation, please contact us anytime.

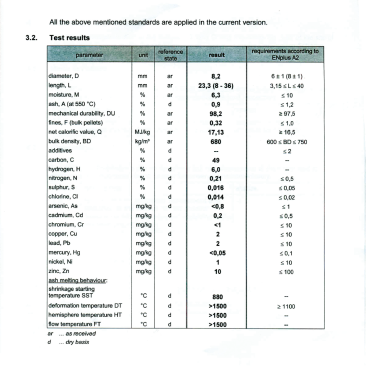

↓ ENPLUS Certificat, Test report and Standard Specification as below.